Every warehouse manager strives to streamline their business operations and enhance productivity. However, this goal becomes increasingly complex as their operation grows larger and competition intensifies. Fortunately, there is a tool that can help businesses stay ahead in this increasingly complex landscape, forklift fleet management software.

Different forklift fleet management solutions provide a range of benefits. Let’s examine the eight key benefits that warehouse managers want from a forklift management system.

Optimize fleet utilization

One of the primary advantages of a forklift management system is its ability to optimize the performance of an industrial truck fleet. For example, warehouse fleet management software can monitor a forklift’s location, usage frequency and downtime in real time to help managers allocate their industrial truck fleet most effectively. Tracking performance metrics and strategically utilizing the trucks can also help cut costs and extend the fleet’s lifespan.

Enhance productivity

Efficiency and productivity are essential to any successful warehouse operation. The real-time data provided by forklift fleet management software can also help streamline work processes. By analyzing a forklift’s travel, movement and loading and unloading times, a manager can identify workflow bottlenecks and other areas in the warehouse that need improvement. The result is a streamlined process and improved overall productivity.

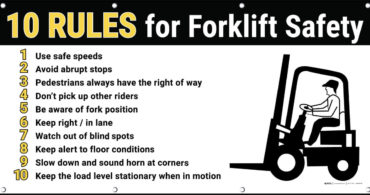

Increase safety

The safety of everyone who works on or near an industrial truck is an essential element of forklift truck fleet management. Again, by analyzing the data provided by a forklift management system, managers can ensure that forklift operators are maintaining proper speeds and operating within any predefined safe zones. In some systems, sensors record any near misses with pedestrians or objects or alert operators and supervisors to potential safety hazards. This level of visibility can help managers create a safer working environment.

Improve inventory tracking accuracy

An inaccurate inventory count is the bane of warehouse (and retail) managers across the globe. Often, forklift fleet management software has RFID technology and barcode scanners integrated into the system that can track the movement of goods throughout the warehouse. However, if those elements are not included in your specific forklift management system, it likely can integrate with an existing inventory management system. This enhanced visibility into inventory movements, not just within your warehouse, but throughout the supply chain process, helps reduce errors in inventory counts, improve order fulfillment accuracy and increase customer satisfaction.

Optimize forklift fleet management and maintenance

Every second an industrial truck is out of commission is wasteful and costly. The best way to ensure that a fleet remains in peak condition is through routine maintenance. A forklift management system helps businesses implement and adhere to a preventive maintenance schedule by keeping track of upkeep needs and overall forklift performance to minimize downtime and costly repairs. Most forklift fleet management software can also monitor elements like fuel consumption and asset utilization to ensure that your trucks are used efficiently.

Ease compliance reporting

Regulatory compliance is important for every warehouse and distribution center, especially those dealing with sensitive or hazardous materials. A forklift management system provides comprehensive reporting tools that help businesses adhere to industry regulations. A manager can quickly generate detailed reports on forklift usage, maintenance history and operator performance. This comprehensive documentation makes routine compliance reporting much easier and takes some (please note that we said “some”) of the stress out of surprise audits and inspections.

Enhance training and performance monitoring

By providing valuable insights into operator behavior, such as speed, maneuvering and safety, a forklift management system can enhance operator training and monitor the performance of a fleet management forklift. Managers can use the data to identify areas where additional training or coaching may be needed to improve skills and reduce the risk of accidents. Forklift fleet management software can also track and record operator certifications and training history, ensuring compliance with those pesky aforementioned regulatory requirements.

Focus on environmental sustainability

Sustainability and environmental responsibility are entrenched business practices that continue to grow in importance. Many of the previously mentioned benefits of a forklift management system also contribute to green initiatives, such as optimizing forklift routes, reducing idle times and monitoring fuel consumption. By utilizing the insights provided by the forklift fleet management software, managers can achieve business goals that align with environmentally friendly practices.

How to manage forklift fleet

There are many examples of forklift fleet management software, and the list of forklift fleet management software is long. However, to find the right one for your business, it’s best to search for a solution that includes the eight benefits of a forklift management system while also addressing the unique needs of your business.

Texas Motive Solutions also wants to understand and accommodate the unique needs of your business. That’s why we offer our complimentary forklift fleet performance analysis that ensures you’re utilizing the best forklift batteries and accessories for your fleet’s requirements. Please, give us a call at (888) 316-2459 or fill out this form to learn about our services and discover everything we can do for you.