A forklift is a type of truck that uses mechanical advantage to lift, turn, or push objects. It is powered by an engine, and the design allows it to carry loads above its own center of gravity—this is known as “self-cant.” It is typically used in warehouses and factories for materials handling.

The following forklift names are also commonly used for this machinery:

- Fork-lift

- Forklift Loader

- Barge

- Forklift Truck

What is the Purpose of a Forklift?

A forklift is a piece of equipment used to lift or move heavy objects. It reduces the amount of manual lifting that must be done using an engine-powered device, making the task easier and faster. Typically, forklifts use an engine to lift against gravity and allow them to collect loads from above the vehicle’s center of gravity for easier handling.

Forklifts are used in a wide variety of applications. They are used extensively in factories, warehouses, and construction sites. They can also be found in many other businesses or even in personal use by some people. For instance, they are often used to move objects around a warehouse or store. They are often used to move goods in warehouses as an alternative to manual labor. Plus, a forklift can lift a weight that would be too heavy for one person to lift.

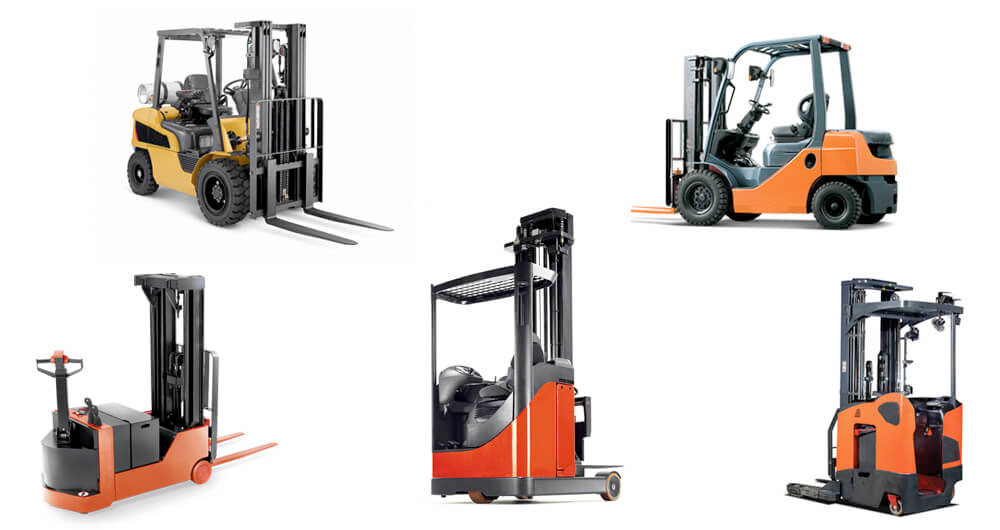

What are the Different Types of Forklifts?

Because forklifts are used so extensively, it is important to know all of the types of forklifts available. With that in mind, the following covers the most common forklift types and their uses.

Forklift Types

Trolley Lift: A Trolley Lift is a type of forklift that can be raised by pushing on the front or rear of the vehicle. These lifts will usually have a “T” handle with two wheels at the center on which it is operated. The common rental trolley lift has two wheels (tires) at the very front and two tires at the very back. Another name for this kind of forklift is a “Goliath” for obvious reasons. This type of lift has numerous advantages in that it can be driven in both directions, it can turn easily in small spaces, and when elevated, it can carry heavy loads with ease.

Counterbalanced Lift: A Counterbalanced Lift is a type of forklift that uses counterweights to balance and raise the forklift. Most of the weight of the lift is usually in a large pillow block mounted on the bottom or below the center of gravity.

What are the Different Sizes of Forklifts?

There are three basic forklift sizes, and they have evolved over time with the types of usage. The most used sizes would be the 20-30 ton, 25-35 ton and 40-50 ton units. However, many companies may change their size requirements as they see fit.

What are the Benefits of Each Size of Forklift?

All three forklift sizes can be used to move a range or variety of loads, but there are differences in which loads each size can lift. There are many different types of forklifts, but what is the purpose of each? Let’s take a look at the three sizes of forklift and their uses.

20 Ton Forklifts

The most common size of forklift is the 20 ton. These units are used for light to medium weight loads. This size of forklift can lift objects from 2,000 lbs to 15,000 lbs depending on the load rating (capacity).

Pros: This size of forklift is an economical choice since it can lift many types and sizes of objects. It also has a high horsepower which allows for increased speed and maneuverability in tight spaces.

Cons: Very low ground clearance limits the ability to access some areas and obstacles. Also, this unit is limited in lifting capacity, so it may not be able to carry large or heavy loads.

25-35 Ton Forklifts

The 25-35 ton forklift is used for heavier loads and is able to lift heavier objects than their smaller counterparts. This size of forklift is used for very heavy items. These units have a load capacity from 20,000 lbs to 40,000 lbs.

Pros: This size of forklift can carry a much larger and heavier load than the smaller forks and is more suited for heavier tasks such as moving pallets and very large loads. While it has a high weight capacity, it also has an equally high cost per ton, making it a more expensive option than the other forklifts.

Cons: These units have a high cost and cannot go through narrow spaces. This size of forklift is also very large and heavy, which may limit the size that can be used inside of a building. The extra size and weight can be a problem if you need to move something, like a piece of equipment, into tight places.

40 Ton Forklifts

The 40 ton forklift is used in factories, warehouses, moving companies, industrial parks, etc. If you plan on moving large or heavy loads from place to place then this unit would be best for you! These units are ideal for moving things from one location to another within the same facility.

Pros: The side of this big forklift makes it ideal for moving large and heavy loads because it is designed to hold a lot of weight and has a high capacity. Also, this forklift can lift heavier objects, making it possible to move very large and heavy objects like containers or machinery.

Cons: The weight of the unit is very high, so it may not fit in some areas or even be able to enter the building that you are trying to move the load into. Also, this type of forklift has limited maneuverability, so when moving, it will have a hard time doing tight turns or going up and down ramps where you may be restricted.

Cost Comparison

Cost is one of the most significant factors when considering a forklift purchase, whether it be a construction forklift or warehouse forklift. However, this should not be your only consideration when purchasing a lift; while cost is important, so is safety and quality (which will affect cost). Machines that do not meet required or specific standards are more expensive than those that do.

Choose Texas Motive Solutions

Do you have additional questions about forklifts? We will gladly connect you with one of our partners.

Texas Motive Solutions offers best-in-class motive power solutions that exceed expectations. From forklift battery repair to insight into reducing operating costs, our service team is here to help! Contact us today to learn more.