Renting or buying? It’s one of the great philosophical debates that has plagued humans for millennia, just like “Chocolate or vanilla?” and “Cake or pie?” So, whether you rent a forklift for a day or buy one for its lifetime, the decision is based on what’s best for your company.

The COVID-19 outbreak disrupted life across the globe. One impact of the pandemic was a worldwide disruption of the supply chain. While supplies are rebuilding and deliveries normalizing, many companies are still experiencing long lead times for new material handling equipment. Forklift rentals provide a solution during the long wait for new equipment.

Another causality of long lead times is forklift batteries and chargers failing because they’re not being used. If you need help maintaining your forklift batteries and chargers while waiting for new equipment, please get in touch with Texas Motive Solutions at (888) 316-2459 or fill out this form. We can help!

Renting a forklift has many advantages for companies looking for flexible and cost-effective material handling solutions, but it is not the correct move for every company. For businesses with consistent, long-term requirements, buying one or a fleet of forklifts could be much more cost-efficient over the equipment’s lifespan. So, how much is it to rent a forklift? Well, when it comes time to consider renting or buying, here are some factors to keep in mind.

Benefits of forklift rental rates vs. purchasing

Money savings

As with all important business matters, the financial impact on your bottom line must be a primary consideration. There are a few ways that renting a forklift can save money. Purchasing a forklift requires a significant up-front investment. If you rent instead, that initial capital can be held or spent on other projects. Having this cash available can be significant for small and medium-sized businesses. However, investing in a forklift or two can be more cost-effective over time. A careful analysis will help determine how to spend your forklift funds.

Flexibility

If your business is impacted by seasonal demands or just general uncertainty, checking into forklift rental cost is likely a sensible business decision. The ability to scale up or down based on business needs, such as during peak seasons or for specific projects, is significant and more economical than purchasing and maintaining a permanent fleet.

Fewer administrative tasks

Owning a forklift means dealing with equipment registration, insurance and compliance issues. There’s also the eventual challenge of selling or disposing of the fleet once it has served its purpose. None of those undertakings are the worst things in the world, but they can be a hassle. Renting forklifts does not mean you’re completely free from paperwork, but there is much less of it, and you never need to deal with obsolete equipment.

Rent to own

This is not referencing a literal “rent to own” scenario (although that may be an option in your area; we don’t know). Instead, renting forklifts allows businesses to try out specific equipment before making a purchase. Renting can also help you avoid work stoppages if your equipment has broken down or you’re dealing with another emergency.

Factors that influence forklift rental prices

Before you commit, you need to know how much is it to rent a forklift. Well, many factors can cause forklift rental prices to be higher in one location and lower in another, including:

Length of rental

How long you need a forklift is a fixed part of forklift rental pricing. You may walk into a forklift dealer, see a sign proclaiming, “Rent forklift for a day,” and think, “For a day! What a bargain.” Well, the shorter the rental, the higher the rate.

In general, forklifts are rented daily, weekly or monthly (you won’t see many, if any, places quoting a forklift rental cost per hour). While someone who needs a forklift for a few months will pay more than someone who needs one for a couple of days, the average monthly price is considerably less than a weekly or daily rate. A monthly rental may also have perks included in the contract, such as maintenance packages and equipment upgrades, that aren’t included in a short-term lease.

Equipment type

Forklift rental rates are also directly impacted by the type of equipment you need. Smaller equipment, such as a reach truck, costs significantly less than a large industrial workhorse, like a telehandler. Other factors influencing forklift rental pricing include load capacity, fuel type and attachments. Specialized and high-capacity forklifts generally have higher rates, too.

Demand

If a forklift is in high demand, it will have a correspondingly high rental pricing. Factors impacting demand include peak seasons (when many businesses require forklifts) and low rental supply.

Another factor is geography. If you reside in an area with high living costs or where equipment demand is generally high, rental rates will likely be elevated. Economic conditions can also impact rental costs. For example, demand may be up in times of economic prosperity, leading to higher prices.

Rental company

It would be a mistake to overlook this aspect of forklift rental pricing. The company where you rent the forklift significantly impacts the rates because it literally sets them. Of course, the rental company is affected by the above factors and competition from other forklift dealers. However, some companies offer incentives that others do not. Researching multiple rental companies in your area to find the best prices and bonuses can pay off.

How much does it cost to rent a forklift?

Below are price ranges for some of the most popular forklift rentals. Remember these are only estimates and that prices vary by region.

Electric three- and four-wheel counterbalanced forklift rental rates

An electric motor powers these forklifts, and they utilize cushion tires suited for flat, indoor surfaces.

Load capacity: 3,000 to 4,000 lbs.

- $190-$360 per day.

- $450-$700 per week.

- $1,125-$1,650 per month.

Load capacity: 5,000 to 6,000 lbs.

- $225-$400 per day.

- $500-$800 per week.

- $1,350-$1,850 per month.

Load capacity: 7,000 to 10,000 lbs.

- $300-$450 per day.

- $650-$950 per week.

- $1,650-$2,300 per month.

Internal combustion engine (ICE) forklift rental rates

These machines are powered by diesel, gasoline, propane or compressed natural gas and typically operate outdoors.

Load capacity: 3,000 to 5,000 lbs.

- $200-$350 per day.

- $450-$650 per week.

- $1,000-$1,500 per month.

Load capacity: 6,000 to 8,000 lbs.

- $280-$450 per day.

- $500-$750 per week.

- $1,250-$1,800 per month.

Load capacity: 10,000 lbs.

- $320-$525 per day.

- $550-$825 per week.

- $1,600-$2,000 per month.

Load capacity: 12,000 to 15,500 lbs.

- $400-$550 per day.

- $850-$1,100 per week.

- $2,400-$2,700 per month.

Load capacity: 16,000 to 21,500 lbs.

- $300-$700 per day.

- $850-$1,200 per week.

- $2,500-$3,000 per month.

Load capacity: 22,000 to 36,000 lbs.

- $750-$900 per day.

- $1,700-$1,900 per week.

- $4,800-$5,500 per month.

Electric-powered pallet truck rental rates

Pallet jacks are one of the most rented industrial machines.

Load capacity: 4,500 lbs.

- $60-$130 per day.

- $150-$325 per week.

- $450-$800 per month.

Load capacity: 6,000 to 8,000 lbs.

- $80-$150 per day.

- $200-$375 per week.

- $650-$950 per month.

Reach truck rental rates

A reach truck’s rental price is based on lift height because they all have the same load capacity.

Lift height to 258 feet

- $200-$280 per day.

- $450-$550 per week.

- $1,300-$1,550 per month.

Lift height greater than 258 feet

- $230-$300 per day.

- $450-$600 per week.

- $1,500-$1,800 per month.

Hidden costs, a.k.a. “It costs how much to rent a forklift?!”

Once you decide to rent one or more forklifts, carefully read the contract before signing on the bottom line. Some unexpected fees tend to lurk in many rental agreements, such as:

Delivery and pickup charges

Your rented industrial trucks need to get from the rental location to your place of business, and they’re not making it down the highway. So, unless you own a truck that’s rugged enough to transport a forklift, you’ll need to pay someone to move your trucks.

Rental companies typically charge for transportation to and from the rental site, and the further away your business is located, the more it will cost. The best way to prepare for delivery and freight charges is to get in front of them. Ask about delivery fees early in the negotiations and keep them in mind as you shop. That way, there will not be any transportation-related surprises when the invoice hits your inbox.

Insurance

First, the good news is that the rental facility will likely have insurance to cover any damage to its equipment. If your business covers the costs, they’re probably already baked into the rental price.

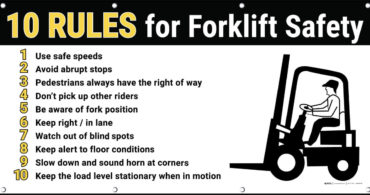

Now the, not really bad, but also not great news. Forklifts bump into stuff. Even the most careful driver will likely nick a rack, maybe scrape a wall. Forklift accidents happen, and those are minor examples. In fact, forklifts rank seventh on OSHA’s list of the top 10 most frequently cited standards. The most recent OSHA statistics state that there are approximately:

- 85 fatal forklift accidents per year.

- 35,000 accidents with serious injuries.

- 62,000 non-serious accidents.

Any damage or accidents that occur on your property are likely your responsibility. Be sure to carefully review the insurance coverage to determine whether the rental facility’s basic coverage is sufficient. Otherwise, you will need additional coverage to protect your business.

Fuel costs

If you’re renting an indoor forklift, that forklift will have a battery, and that battery will have a charger, both of which are (generally) included in the rental price. So, no extra costs there.

However, if you need an outdoor rough terrain forklift, those beasts run on either gasoline, diesel, propane or compressed natural gas. Like renting a car, you need to pay for gas in every vehicle (often, the machine is delivered with a full tank and expected to be returned with a full tank). If you are renting a propane-fueled forklift, ask your rental facility if the tank is included in the agreement and if refilling it is your responsibility.

Overtime

Most rental contracts include a usage clause that covers a traditional eight-hour workday, 40-hour work week or 160-hour work month. However, if you need the machine to spend a little (or a lot of) extra time at the worksite, you are responsible for those overtime costs.

Overtime rates typically relate to the size of the industrial truck. In other words, the overtime rates for a 5,000 lbs. load capacity forklift are less than those for a 36,000 lbs. load capacity forklift.

Return fees

Regardless of the type of forklift and the environment where it is used, there will be a clause in the rental contract specifying the condition of the lift truck. You may be on the hook to repair any damages or even cleaning costs if the lift is returned in an especially filthy condition. Some companies may require a security deposit that is only returned based on the forklift’s condition.

Be sure that you completely understand the rental company’s expectations regarding the forklift’s condition and cleanliness. Also, thoroughly inspect the forklift and document any existing damage before accepting it for rental.

Getting the best forklift rental pricing

To ensure that your forklift rental cost is favorable, start online. Look for forklift rental companies with the highest ratings and review previous customers’ experiences. Once you narrow the field to a few companies, tour the facility to get an idea of the age and condition of its fleet. Get quotes to compare the daily, weekly and monthly pricing structures. Be sure to ask about every potential hidden fee. (Also, make sure they have your desired forklifts in stock. Some companies have limited availability, especially during peak seasons.)

Next, it’s time to negotiate. Here are a few opportunities for saving money.

- Bundled services: ask if discounts are available if you purchase multiple services, such as maintenance packages and equipment upgrades.

- Volume discounts: bargains may be available if you need several forklifts or a long-term rental.

- Leverage competing offers: this could be where all that research pays off: get bids from multiple companies, then play them against each other.

Speaking of rentals, if you need additional forklift batteries to get through a busy season, Texas Motive Solutions has plenty of forklift batteries and chargers available to lease.

Please call us at (888) 316-2459 or fill out this form to learn more about our rental program, discover our complimentary forklift fleet performance analysis and see how our industrial battery services help keep your fleet up and running.