Forklift Power

Texas Motive Solutions is an authorized distributor and service provider of Hawker Powersource, Inc. batteries, chargers and accessories, with locations in Dallas, Fort Worth, Houston and San Antonio, Texas. Along with representing Hawker Powersource, Inc.—one of the best motive product lines in the industry—Texas Motive Solutions provides unmatched sales, service and technical support for forklift dealers in the Texas market.

Figure out which battery is good for you in 6 questions

Forklift Batteries for Sale

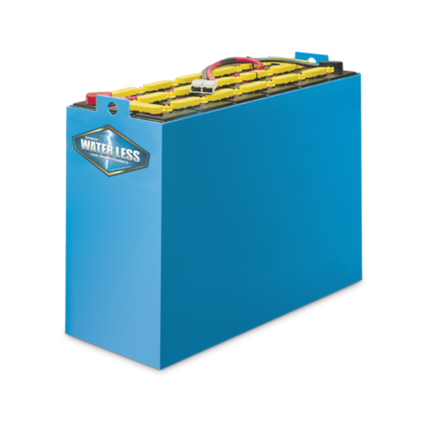

Power your forklift fleet with HAWKER® superior lead-acid, Thin Plate Pure Lead and lithium batteries

Texas Motive Solutions is proud to offer the full line of HAWKER® lead-acid, Thin Plate Pure Lead (TPPL) and lithium-ion electric forklift batteries. As the exclusive HAWKER® sales and service provider in most of Texas, TMS maintains a robust HAWKER® forklift battery inventory at our Dallas/Fort Worth, Houston and San Antonio locations. Whether you’re looking for a forklift battery for sale or rent, we’ve got you covered.

Electric forklift battery FAQs:

What if we want to water our own forklift batteries, can TMS show us how?

Absolutely! We understand it makes sense for some warehouse operators to utilize employees to handle battery for forklift watering duties. TMS customers can contact us to schedule complimentary employee training sessions as needed.

Can improper watering turn into a safety hazard in warehouses?

Yes! When acid gets trapped in the battery plates, you can’t maintain appropriate fluid levels. Eventually the fluid overflows, and acid spills on the batteries and floor. When employees water batteries improperly, they can get acid on themselves, which could cause dangerous acid burns.

What happens if you don’t water forklift batteries properly?

Any deviation from the recommended battery watering schedule can result in overflow or lack of fluid, either of which can damage forklift batteries and lead to unnecessary repair or replacement costs. Unfortunately, it’s rare that warehouse operators do a good job handling their own forklift electric battery watering.

What are common safety issues associated with a forklift charging station?

Several safety issues exist that can be easily managed when you set up the forklift charging station properly and employees are trained to handle batteries and chargers safely. Some forklift charging best practices include:

- Require battery room attendants to always wear proper PPE—including gloves, aprons and eye protection—while watering batteries to avoid contact with battery electrolyte.

- Keep open flames and sparks away from batteries during charging, as batteries produce combustible hydrogen gas during the gassing phase of battery charging.

- Make sure all battery and charger cables are clean and undamaged because old, cut or damaged cables can cause shorts and potentially produce an electrocution hazard.

- Properly mount chargers up off the floor to prevent forklifts from running into them and causing potential electrocution hazards.

TMS can guide you on best practices for setting up a battery charging area and train employees on safety protocols. We’re also happy to install the equipment and accessories necessary to help ensure your space for charging forklift battery inventory is safe.

How do I know if my forklift application is a good candidate for opportunity charging, rapid charging or IONIC charging?

Every application is unique, which is why TMS recommends performing a thorough evaluation of each customer’s forklift utilization. During our analysis, we evaluate available idle times, based on the time the application allows for charging and how many hours the lifts run per day. This insight dictates which charger technology best suits the specific application and helps us formulate the optimum solution for the customer.

Why choose Texas Motive Solutions as your forklift battery provider?

TMS is committed to finding the most efficient and economical forklift battery solutions for Texas forklift fleet operations. By performing a complimentary forklift fleet power analysis, we’re able to pinpoint operational inefficiencies and identify the best solutions and a forklift batter price to meet each customer’s needs.

Through our partnership with HAWKER®, we also offer the widest variety of forklift battery options in the market and the lowest total cost of ownership available. Our experienced and responsive sales and service team is here to serve you! To learn more, contact the TMS location nearest you today.