For many companies, supply chain costs constitute a significant part of their annual budget. However, that noticeable supply chain cost wedge on the budgetary pie chart also represents a prime opportunity to optimize performance and improve revenue.

Anyone involved in the complex industry of supply chain management thinks about the supply chain and supply chain management costs a lot. Before the year 2020, almost everyone else in the world did not.

That all changed around March 2020, when people would walk into a grocery or big box store hoping to buy canned goods, toilet paper, cleaning supplies, paper towels or hand sanitizer and found only empty aisles. The lockdowns and worker shortages caused by the Covid-19 pandemic disrupted the supply chain in ways that were impossible to predict. (This is not to say that these were unknown weaknesses in the supply chain. Just that the international scope and impact of the pandemic were unprecedented.)

Fast forward, and even though the store shelves are fully stocked, the pandemic’s impact on the supply chain is still felt today. While many of these effects are negative, for example, industries across the country are still contending with high material and labor costs, some are positive. Many industries are shoring up the supply chain weaknesses exposed by the pandemic, while others are using the lessons learned from Covid-19 to lower their total supply chain costs.

The supply chain

The supply chain is every step necessary to get a finished product or service to the customer. Examples of these stages include sourcing raw materials, refining them in production, transporting bulk packages to a distribution center or retail store and selling them to a customer.

Some supply chains are short and direct, while others are lengthy and complex. Regardless, all supply chains have costs involved, often hefty costs, and lowering those costs is the primary focus of supply chain managers everywhere.

Supply chain cost definition

As mentioned, some industries have supply chains that are essentially a straight line while other weave and turn all over the place. However, as separated as some of these chains may seem, supply chains are really one large global supply chain. That interconnectedness means when one price goes up, such as labor, energy or transportation, others tend to follow.

That’s why supply chain managers frequently pull their hair out over costs. Their expenses are consistently fluctuating. Fortunately for these managers, there is a formula to help them monitor their supply chain costs.

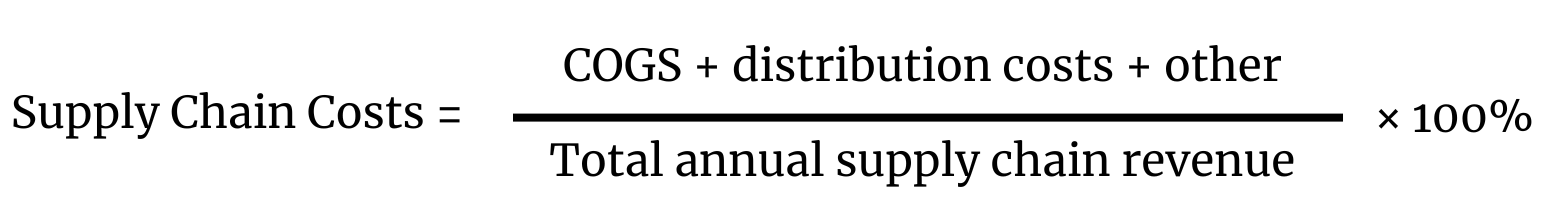

The total supply chain cost ratio is a way to determine a company’s total spending while performing its supply chain activities. These costs are measured as a percentage of revenue. The formula is:

- Annual cost of goods sold (COGS), plus

- Total annual distribution costs, plus

- Other supply chain costs (which include a variety of industry-specific operational expenses), divided by

- Total annual supply chain revenue (generally, this excludes revenue from selling company or supply chain assets), multiplied by

- 100%

After running the numbers, a supply chain manager wants to see a low percentage because that indicates better performance. If the result is a high percentage, the manager knows that their company is likely spending more than is necessary (or sensible).

Total procurement price (and how it’s different from supply chain costs)

There is another element that keeps supply chain managers up at night, and that is the total procurement price.

Procurement refers to the process of acquiring goods or services from external sources. It’s all about finding the best merchandise at the right price, quality and quantity. The total procurement price includes finding suppliers, negotiating contracts, buying goods and maintaining relationships with suppliers.

Procurement (and the procurement price) is essential to the supply chain, yet the supply chain is much more than procurement. The supply chain (and every single supply cost) begins with procurement and continues through every process required for the product to reach the end user.

Also, supply chains tend to have longer timelines because they frequently deal with components, products or services from overseas. Procurement can be lengthy, but it can also be a simple trip to an office supply store to buy pens and paper.

However, as you’ll see below, procurement is a leading supply chain cost driver.

The main reasons for supply chain cost

Supply chain cost is a concern for nearly every company. When supply chain costs are out of whack, they pose a significant risk to a business’s bottom line.

Unfortunately, once the supply chain costs become an issue, getting them back in line can be challenging. One reason is the global nature of supply chains. Because most supply chains are interconnected, reducing costs in one area of operations can cause a rise in another. Another risk of lowering a supply chain cost is that it can cause a conflict with your or another department’s key performance indicator. For example, reducing inventory costs can cause a drop in on-time delivery performance and customer satisfaction. Without being careful, price cutting can cause disruptions to the supply chain costing a company significant revenue.

Some of the leading causes of increases in supply chain costs include:

Procurement

Ah, our old friend, procurement is acquiring goods or services from external sources. Unfortunately, inconsistent suppliers with their fluctuating prices or delivery times can cause a reaction that extends along the supply chain.

To combat unexpected (and unwanted) issues with procurement requires some legwork upfront. Instead of going with the first supplier that comes along, you know, the one with the flashy presentation and surprisingly low price point that seems too good to be true, delve into their past performance to discover how they can offer those prices (and how long the bargain may last.) Do the same extensive research with multiple suppliers using historical and current data.

While this process can be time-consuming (and may cost a few dollars upfront), finding reliable suppliers with competitive prices who can deliver on time when and where you need it is worth it. The result should be sustainable procurement costs and reliable supplier performance.

Production

Continuing along the Ps of the supply chain brings us to production. However, this is not a cost that (directly) affects every business. While all goods must undergo some form of production, many companies purchase products post-production, meaning the production cost is already factored into the final price (and these price increases tend to be gradual and somewhat predictable).

Fluctuations in production costs primarily (but not exclusively) impact manufacturing companies. There are many reasons for spikes in production costs, including old or improperly maintained equipment. For example, a common issue with older equipment is that it takes longer to start or set up (and sometimes operate). Naturally, a slow start also leads to increased worker and equipment downtime, which harms overall productivity.

Inefficient management is also a problem that plagues many manufacturing facilities. This can mean poor workforce management, resulting in unproductive hours and overtime. However, it can also be inefficiently utilizing equipment and production operations.

A final issue, and this is a more significant concern for bespoke manufacturers, is having to make changes to existing work. Any mistake in the production process, such as if a client request is overlooked or incorrect, must be corrected, which can lead to employee overtime, reduced margins and missed deadlines on other projects.

The best way to stay ahead of production issues is to monitor production strategy and costs carefully.

Transportation

Whether filling up at the gas station or trying to purchase an airline ticket, transportation is expensive these days. One of the primary reasons for high transportation costs is the high price of crude oil, which has risen significantly (and erratically) since the mid-2000s.

However, the supply chain faces another transportation challenge: a supply and demand imbalance. The growth of ecommerce has stressed the transportation sector. According to a report from The Department of Transportation, the need vastly outweighs the availability of transport services creating a supply chain bottleneck.

So, with transportation costs being inevitable (and potentially high), there is no room for error regarding planning and routing. If the routes between your suppliers, manufacturers, distributors and customers are all over the place, your total supply chain costs will also be all over the place. Optimizing transportation itineraries can save companies both time and money.

Inventory

In 2016, fast-food fried chicken purveyor Popeyes decided they wanted to sell a chicken sandwich. The decision made sense. After all, Popeye’s sells fried chicken and they were getting smoked by their fast-food competitors in the chicken sandwich department, being that they did not have one. Fast forward to August 2019. Popeyes released its chicken sandwich, and, well, for some reason (social media), America lost its mind. Over a fast-food chicken sandwich. Lines stretched around the buildings and snaked through parking lots as people waited hours for, again, a fast-food chicken sandwich. Granted, one of the better fast-food chicken sandwiches, but still, just a fast-food chicken sandwich.

Anyway, Popeyes did not see this bewildering level of love for its fast-food chicken sandwich coming. To be fair, no one could have seen it coming (fights broke out; a man died, murdered for cutting in line to buy a fast-food chicken sandwich).

This is where we get to inventory. See, Popeye’s had a plan. Given traditional sales projections based on a new product launch, they had enough inventory to last through September (the company even claims they overstocked). There are nearly 3,000 Popeyes stores in the United States, and they all ran out of the chicken sandwich before the end of August.

The Popeyes chicken sandwich is an extreme example of an inventory management issue. However, smaller examples occur every day. Stockpiling too much inventory can damage a company’s bottom line by tying up valuable resources and warehouse real estate, while having too little inventory risks upsetting the consumer (see above).

Inventory is a buffer against chaos, and the goal is always to be able to fulfill demand. One of the best defenses a company has against anarchy is a perfectly stocked inventory to ensure that inventory levels remain at their ideal level.

Last-mile delivery

Last-mile delivery is the final stretch before the product reaches the consumer. This may mean a direct-to-the-consumer delivery, but it can also be dropping off products at a retail store. Last-mile delivery could be considered part of the transportation category. Still, it truly deserves its spot on this list because it has some of the highest delivery costs in the supply chain.

Fuel expenses are one of the leading total supply chain cost drivers. Because last-mile delivery typically occurs on congested residential streets, drivers must maintain lower speed limits and spend time idling in traffic. That idling also leads to labor costs. It’s not the driver’s fault that they are stuck in traffic. Nevertheless, it’s time that could be better spent.

Another often overlooked last-mile cost is the deliveries. According to a Business Insider article, 15% of all online shopping deliveries in urban areas fail to reach their final destination, and more than 1.7 million packages disappear every day nationwide. Theft is the primary culprit but incorrectly delivered packages also play a part. Companies also need to factor in the cost of returns as part of their last-mile costs.

Supply chain costs are unavoidable. However, they can be minimized and optimized with some effort to make your supply chain operations as efficient as possible.

Speaking of efficiency, an essential aspect of the supply chain is warehousing and storage. Functioning at peak efficiency requires a fully operational fleet of forklifts. That’s where we can help.

For all your forklift repair and maintenance needs, please give Texas Motive Solutions a call at (888) 316-2459. We also offer a complimentary forklift fleet performance analysis to guarantee you have the correct batteries for your needs, and our preventive maintenance program keeps your fleet running at its highest performance.

Please fill out this form to learn about our services and discover everything Texas Motive Solutions can do for you.