Forklift Battery Repair

Minimize downtime and maximize the productivity of your forklift fleet

When your forklift fleet fails to perform at optimal levels, your organization loses money. Perhaps your forklift is sitting idle due to a dead battery or forklift battery run times have declined, while forklift downtimes have increased. Most warehouse managers face these problems when managing a forklift fleet.

As your resource for forklift battery replacement, repairs and reconditioning, Texas Motive Solutions can help optimize your return on investment and protect your bottom line. Our team is committed to getting your warehouse operation back up and running ASAP, while maximizing battery life and performance.

Since Texas Motive Solutions is a full-service forklift battery solutions provider—we sell, service, repair and recondition forklift batteries and chargers—TMS offers solutions that fit your needs, not ours. TMS does it all! Plus, your satisfaction is a top priority for us, so you can feel confident the solutions we recommend will align with your operational and budgetary goals.

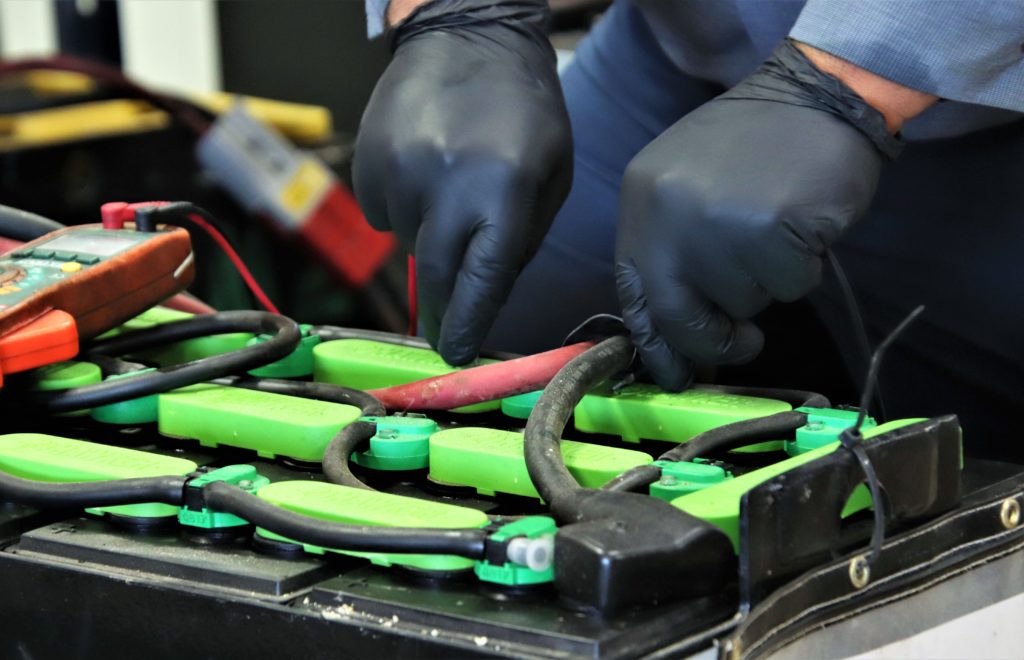

TMS forklift battery repair services

We’ll put our industry-best HAWKER® Powersource, Inc. electric forklift battery maintenance tools and technology to work for you.

- Cable repair/replacement

- Contact tip replacements

- Connector replacements

- Forklift battery cell replacement

- IC connector repair/replacement

- Specific gravity adjustments

- Full 6-hour capacity testing

- Corrosion neutralization and battery washing

- Battery tar sealing

- Complete forklift batteries replacement and reconditioning

- And more!

How the TMS forklift battery repair and reconditioning process works

When your forklift batteries are underperforming—or not performing at all—we’ll send a TMS service technician to your site to troubleshoot the problem right away (typically within 24 hours or less). If we can handle the repair onsite, we will. For example, if a battery cable is broken or contact tip needs replacing, we can usually handle that repair on the spot.

Our forklift battery repair recommendations are based on facts, not guess work

As the exclusive provider of HAWKER® Powersource, Inc. motive solutions and forklift battery repair in Dallas, Fort Worth, Houston and San Antonio regions, we perform diagnostic tests using HAWKER® best-in-class data management technology. The HAWKER® Battery Boss tool allows us to pinpoint problems by assessing battery data such as battery age, number of cycles, discharge and rest times, electrolyte level and more.

TMS’ comprehensive forklift battery reconditioning services go way beyond charging and washing batteries

While some forklift battery service providers do a fine job washing, charging and replenishing acid in batteries, their services often end there. At TMS, we embrace a full-service philosophy and take extra time to fully recondition the viable batteries that enter our shop. (If your battery isn’t worth repairing, we’ll tell you so.)

Get best-in-class forklift batteries services with TMS

Thanks to the insight of the logistics and forklift industry veterans at TMS, we developed a forklift battery repair and reconditioning process rooted in decades of experience analyzing and servicing motive batteries. The goal? To recondition your battery so it looks and performs as close to factory specifications as possible.

Contact us for complimentary, worry-free forklift battery scrap disposal

The Occupational Safety and Health Administration (OSHA) of the United States and the state of Texas have put safety rules and regulations in place because your employees and you have a right to a safe and healthful workplace. In order to comply with regulations established by OSHA Texas companies must dispose of forklift batteries according to OSHA guidelines. If you don’t comply and OSHA traces an improperly disposed forklift battery back to you, your company will be fined.

How efficient is your warehouse forklift fleet operation?

Find out with a complimentary forklift fleet performance analysis from TMS!

At TMS, we work closely with our customers to ensure they purchase the right motive battery and forklift battery charger solutions from day one. In order to accomplish that goal, we dedicate time to learning about the inner workings of the client’s warehouse operation and perform a non-invasive, Power Study to analyze forklift fleet and motive battery performance.

This complimentary service is critical because it allows us to find out:

- Where operational efficiencies could be improved.

- What power requirements your operation really needs.

- What type of forklift batteries and chargers would work best in your application.

- How best to optimize the performance of your forklift fleet.

The HAWKER® HawkerNet™ cloud-based battery management technology we use allows us to analyze battery performance in real time. This tool is also easy to use and non-invasive, so your forklift drivers won’t even know it’s there. Because the Power Study data is so precise, we can propose a solution tailored to you needs, which means you won’t waste money on batteries and chargers you don’t need.

Again, we aim to get the right equipment into your facility from the outset. When your power requirements change or equipment is aging out, we’re happy to come in and perform another Power Study at no cost to you.