Routinely adding water to a lead-acid battery is essential to keep it in prime condition and running safely. In fact, the importance of forklift battery water is second only to charging when it comes to maintaining a lead-acid battery.

Water is a crucial component of a lead-acid battery. Without enough water, a lead-acid battery cannot function properly.

What happens if a battery runs out of water?

A lead-acid battery (also known as a flooded lead-acid battery or wet cell battery) is a rechargeable battery that consists of flat lead plates immersed in an electrolyte solution. The solution is a mix of sulfuric acid and water. The size of the lead plates and the amount of electrolyte defines how long a battery remains charged (i.e., the battery’s hours of use).

Lead-acid batteries generate electricity through a chemical reaction that causes the sulfate in the sulfuric acid to bond with the lead plates. Recharging the battery reverses this reaction, so the sulfate returns to the sulfuric acid. Both processes cause water in the battery to evaporate, lowering the electrolyte level. Sulfuric acid does not evaporate, so its level remains constant.

If the electrolyte solution drops too low and the lead plate is exposed, the sulfate bonded to the lead can harden. This damage to the lead plates limits their ability to hold a charge and reduces their hours of use.

When should you add water to a battery?

Watering should be a routine part of your weekly battery maintenance. In general, watering your forklift batteries every five days is recommended. However, new batteries may need less watering, while older batteries may need more frequent watering.

Always add water after charging the battery. Adding water before charging can cause the battery to overflow. When a battery overflows, it loses some sulfuric acid, which is dangerous and shortens its life. The only exception is if the lead plates are exposed. You want the plates damp while they charge, so they don’t overheat and become damaged. Should your battery overflow, it’s advisable to call a service technician to ensure it functions safely and appropriately. Also, never add sulfuric acid to a battery. Doing so is extremely dangerous and can damage the battery (and the person trying to add it).

There are several ways to tell if a battery needs watering.

Many lead-acid batteries come with a forklift battery water level indicator. For example, the Hawker PowerSeries Electrolyte Level Sensor glows green when the electrolyte level is okay, shines red when the battery needs water and blinks red when the electrolyte level is low for 10 days or longer.

If the battery does not have a forklift battery water level indicator, the next best way to check a battery’s water level is with your eyes. You may need a flashlight to see the water level in each cell. The fluid should be about a half-inch to three-fourths of an inch above the lead plates. If the fluid is below that, it needs to be topped off.

How to fill water in battery

Before attempting to water (or perform any maintenance on) a battery, always put on personal protection equipment. The recommendation is to wear protective goggles, gloves and a face shield.

There are three different forklift battery watering procedures.

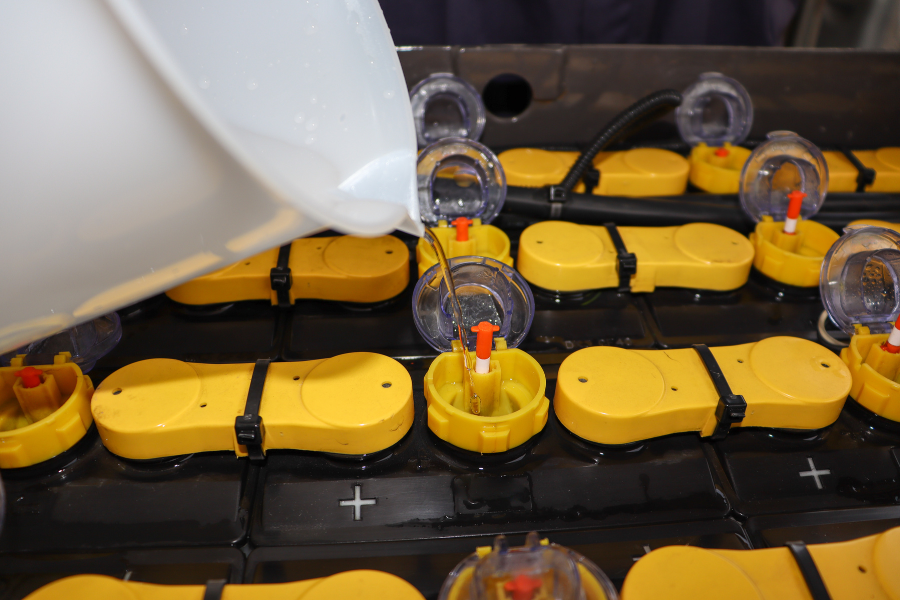

The first for battery refreshing is a forklift battery water-filling system. This system is a series of hoses that cover the top of the battery and attach to each cell. It has a single input that needs to be attached to a water source. The system will shut off once every cell receives the correct amount of water.

The second method utilizes a specialized watering gun. A technician uses the gun to fill each cell to the proper level manually. These devices shut off once the water level reaches the tip of the nozzle.

The third method is a gravity feed system. A large water tank hooks to the ceiling, and a technician uses a hose to fill each cell manually. The technician may need a flashlight to check each cell’s water level visually.

What kind of water do you put in a battery?

Distilled water is the best type to use in a lead-acid battery. The electrolyte solution in a lead-acid battery is a delicate balance. If you use water that is dirty or full of minerals, it adds particulates to the mix that can damage the battery.

For example, even though it looks clear, tap water contains minerals that can harm a battery. Even a small amount of tap water can irreparably shorten a battery’s life. Water that has passed through a water softening system is even worse because that process adds minerals to the water.

If you are unsure if you are using a distilled water battery filler, use a litmus strip to test it. You want your water to measure between five and seven on the PH scale.

At Texas Motive Solutions, we are focused on forklift battery maintenance. If you need watering services or any forklift battery repair, our experienced service team can typically get to your site in 24 hours or less. Once we reach your site, our technician will analyze the issue, propose a solution and get to work immediately.

Please call us at (888) 316-2459 or fill out this form to learn about our services or begin a service request and discover everything we can do for you.